Established in 2022 and located in South Bekasi, PT Exima Maju Perkasa is a leading provider of high-quality component supplies, spare parts, and insulation and refractory products for the industrial sector. Our mission is to deliver exceptional value and ensure customer satisfaction through competitive pricing and outstanding service.

To be the trusted partner in the industrial sector, recognized for our commitment to quality, reliability, and customer service.

To provide superior products and innovative solutions that enhance our clients' operational efficiency and quality.

PT Exima Maju Perkasa was founded in 2022 with a clear vision: to bridge the gap in quality component supply in the industrial sector. Our journey began when we identified a significant demand for reliable spare parts and insulation solutions among local manufacturers.

In our early months, we faced challenges, particularly with clients experiencing high rejection rates in production tests. By offering tailored solutions and high-performance products, we quickly gained their trust, leading to our first major contracts. This initial success laid the foundation for our ongoing growth.

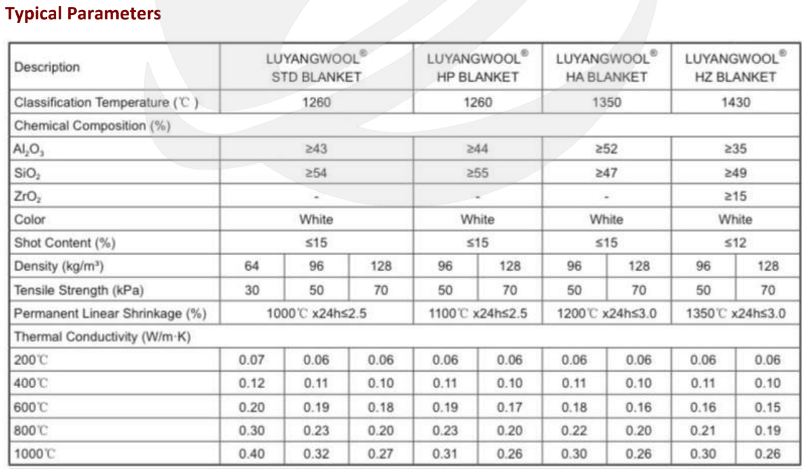

| LuyangWool Blanket |

Luyangwool blanket is high strength, needled insulating blanket that is made from wool bulk.

| Luyangwool Board |

Luyangwool board is manufactured in a wet forming process using Luyangwool bulk and binders.

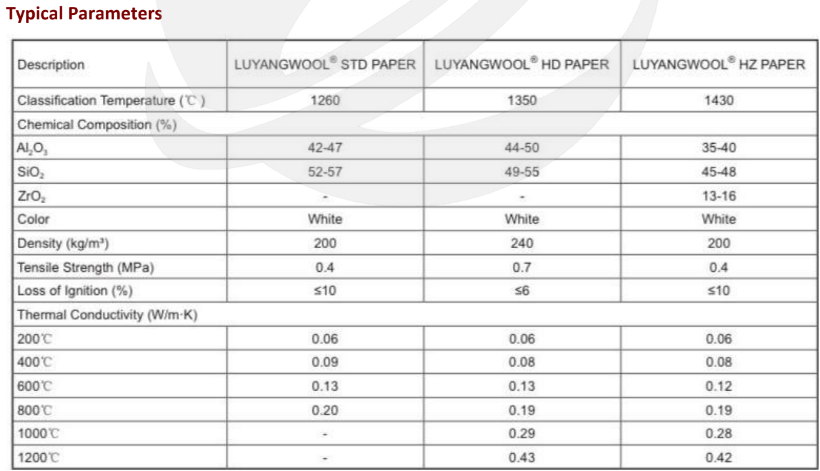

| Luyangwool Paper |

Luyangwool® paper is manufactured by blending Luyangwool® bulk, binders, and additives.

| Luyangwool Basalt Rock Wool Board |

LUYANG BASALT rock wool board for industry has a certain strength.

| Luyangwool Basalt Rock Wool Blanket |

LUYANG BASALT rock wool blanket for industrial insulation.

Luyangwool Basalt fireproofing black rock wool board |

LUYANG BASALT fireproofing black rock wool board, as a kind of black brown rock wool board.

Luyangwool blanket is high strength, needled insulating blanket that is made from wool bulk. The combination of long spun fibers and needling operation produce tough, resilient and strong blankets, which resist tearing both before and after heating. Luyangwool blanket is completely inorganic and available in a variety of temperature grandes, densities, and sizes. Luyangwool blanket can be folded, compressed and encapsulated to produce modules. |

Excellent thermal shock resistance

Excellent thermal stabilty

Low thermal conductivityHigh tensile strength

Low heat storage

Pipe wrap

Furnace and kiln back-up insulation

Chimeny insulation

Annealing furnace linings

Process heater linings

Luyangwool board is manufactured in a wet forming process using Luyangwool bulk and binders Luyangwool board is designed for insulation applications experiencing vibration, mechanical stress and erosive forces. Luyangwool board can reduce energy costs and cycling times due to high insulating capability, as well as serving to protect refractory surfaces from thermal shock and chemical attack. |

Excellent thermal shock resistance

Can be machined, cut and shaped easily

High rigidity and light weight

Low thermal conductivity

Low heat storage

Furnace hot face lining in petrochemical furnace

Furnace hot face lining in ceramic kiln

Board over blanket hot face lining

Back-up insulation to brick & castable

Expansion joints

Luyangwool® paper is manufactured by blending Luyangwool® bulk, binders, and additives. The specialized paper-making process is used to form uniform and flexible paper.Luyangwool® paper is easy to be handled and cut.Luyangwool® paper can be used in a wide range of applications as thermal insulation.It is especially suited to used in gaskets and as a parting medium.

Excellent thermal shock resistance

Can be machined, cut and shaped easily

High flexibility

Low thermal conductivity

Good dielectric strength

Gaskets for high temperature applications

Gaskets for domestic appliances Back-up lining

for metal troughs

Thermal barriers for vehicles

Expansion joints

LUYANG BASALT rock wool board for industry has a certain strength, the fiber structure of which makes itself have the properties of good dimensional stability, thermal stabilityand chemical stability, and also have another three characteristics of excellent heat resistance, corrosion resistance and low thermal conductivity.

The rock wool board for industry is specially used for the equipments of boiler, kiln and distillation tower in the field of petrochemical industry, power plant and industrial manufacture. Products must be stored indoor, when placed outdoor, covering with waterproofing cloth is required

LUYANG BASALT rock wool blanket for industrial insulation, is a kind of rock wool product like roll felt, with the sturdy resilient felt and galvanized iron wire netting or stainless steel wire netting being sewed up with galvanized iron wire or stainless steel wire, and the retentivity of this structure makes rock wool felt not break, and have good flexibility, thermal insulation performance,convenience for construction.

Mainly used in thermal insulation, fire prevention and sound absorption of large aperture pipeline, large storage tank, container, boiler and blast pipe in the field of petrochemical industry, power plant and so on. Product can also be uesd in the place with high temperature, vibration and high fireproof requirements.

LUYANG BASALT fireproofing black rock wool board, as a kind of black brown rock wool board,is specially designed for curtain buildings with high request for fireproofing grade. The product has the properties of high melting points. long fire-resistant limit* resistance to high temperature shrinkage. no corrosion to metal parts and so on, besides ones of common rock wool boards.

LUYANG BASALT fireproofing black rock wool board is filled into the gap between curtain wall and floor slab or partition wall, for fireproofing and cutting off the spread of smoke and gas, and fire blocking in the building gaps including around pipes through the floor slab or wall, can also be used for fire protection separation of the wall between windows in the curtain-wall-system buildings. Besides, the product can also be used as filler of fireproof doors and fire roll shutters in order to enhance the fire

| Reverberatory |

| Rotary Furnace |

Rotary equipment applied in mass processing aluminum slag slag (cold and hot slag )

| Dust Collector |

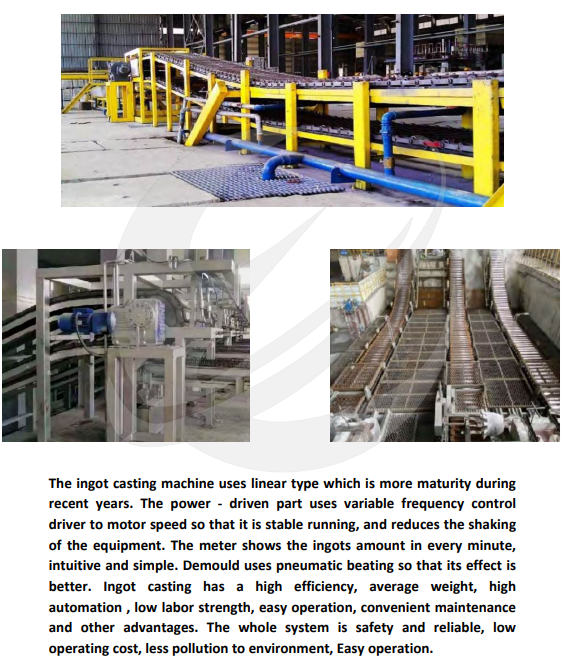

| Aluminium Ingot Casting Machine |

| Wire Rope Winch System |

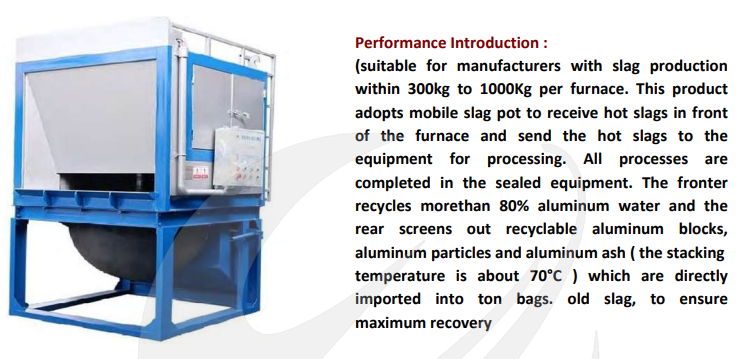

| ASH Treatment Machines |

| Cooling Drum and Dross Size Seperator |

| Billet Castin Mould |

During thecasting process, the liquid aluminum liquid is cooled to make it cast aluminum billet that meet the requirements.

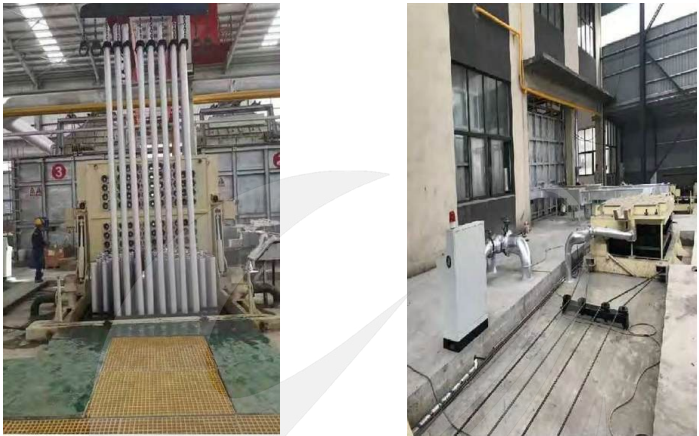

| Degasser |

|

| Metalurgic |

| Regenerative Burner |

| Transfer Ladle |

| Chain |

| Manifold |

| Ingot Mould |

| Felt Cloth |

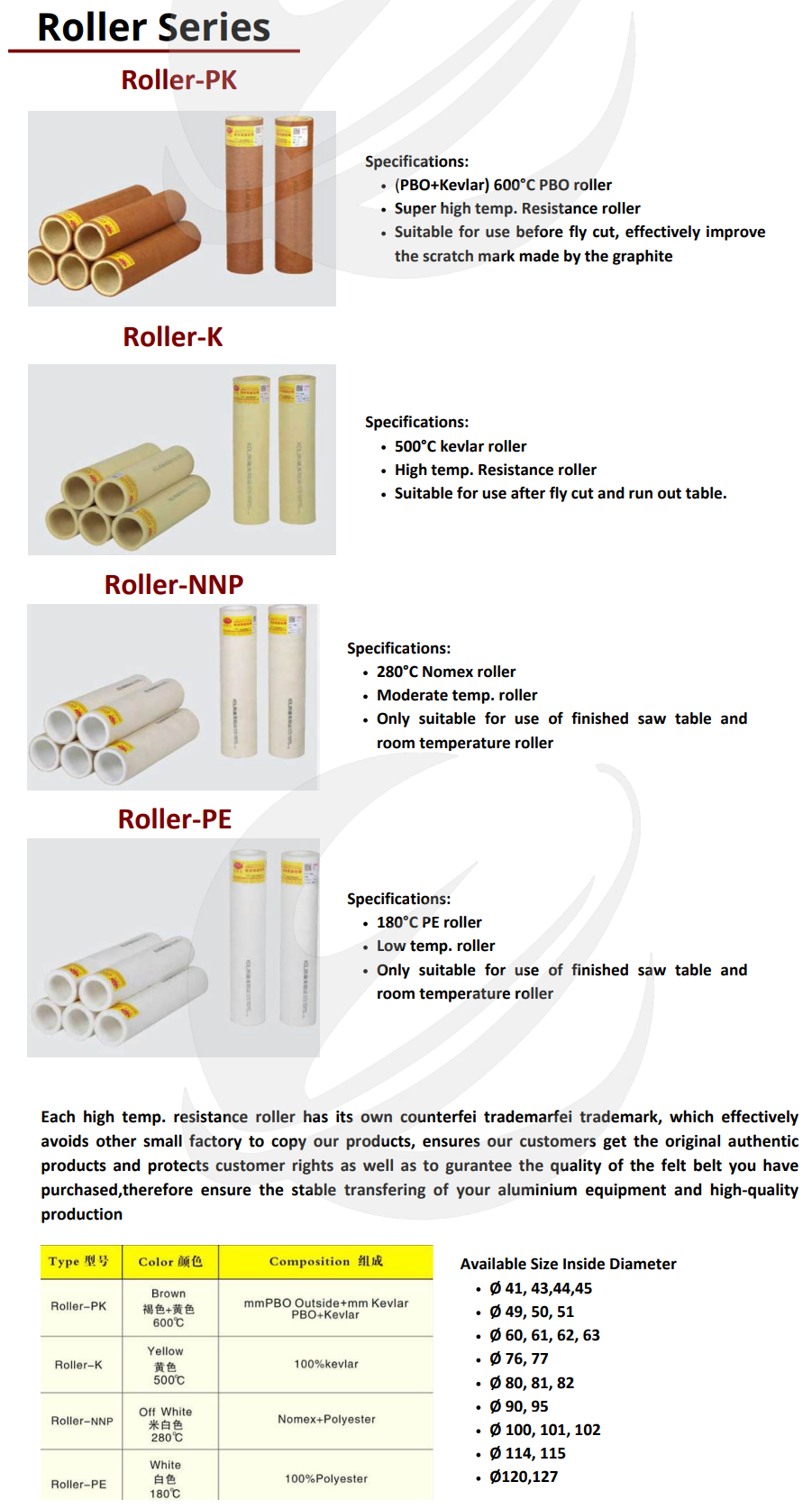

| Roller Series |

| Seamless Conveyor Belt |

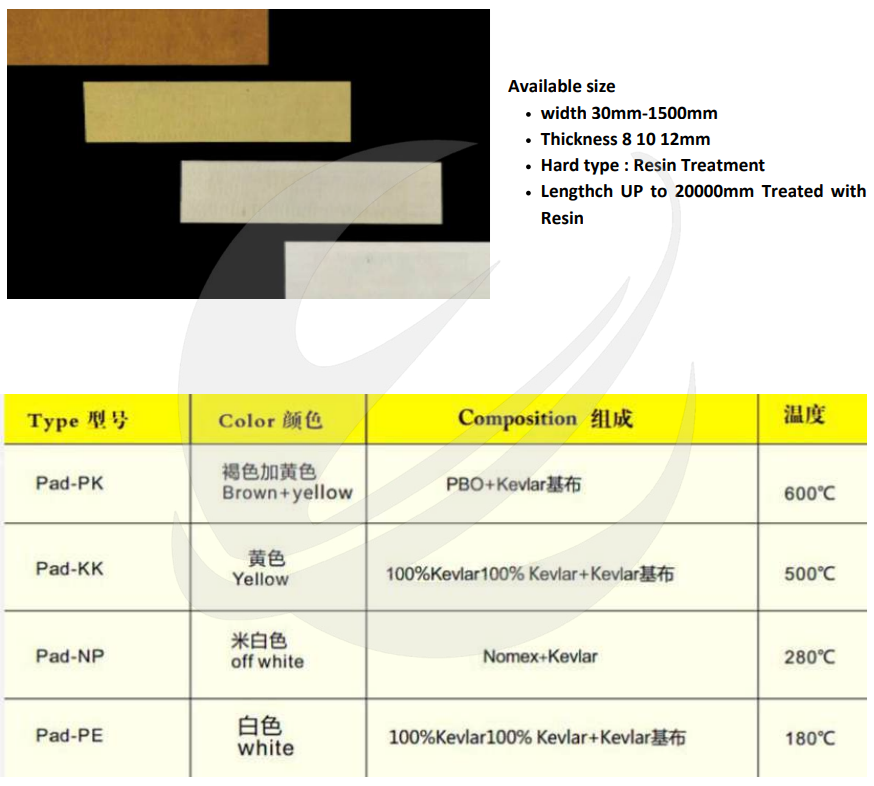

| Felt Pad Series |

| Press Mouth Felt Pad Series |

| Nomex Felt Strip |

| Spacer Sleeve |

| Timing Belt Series |

| Galvanized Steel Roller |

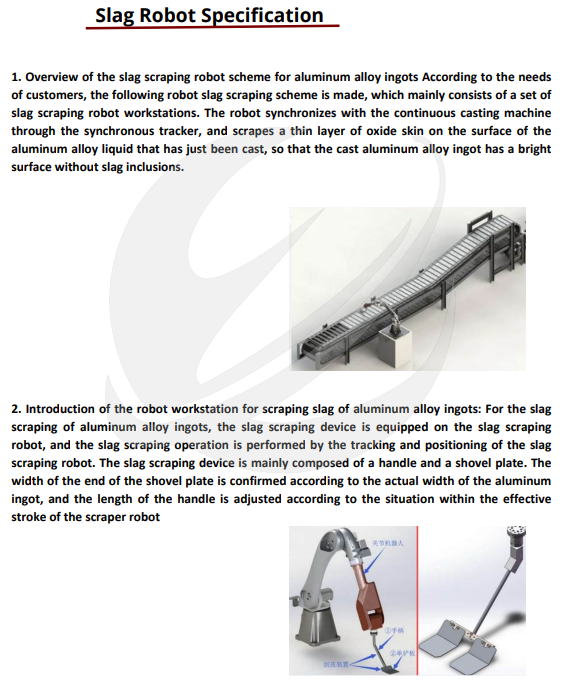

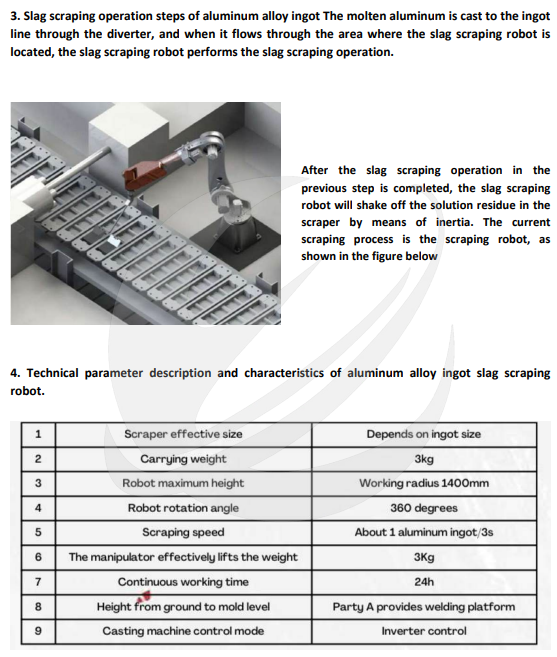

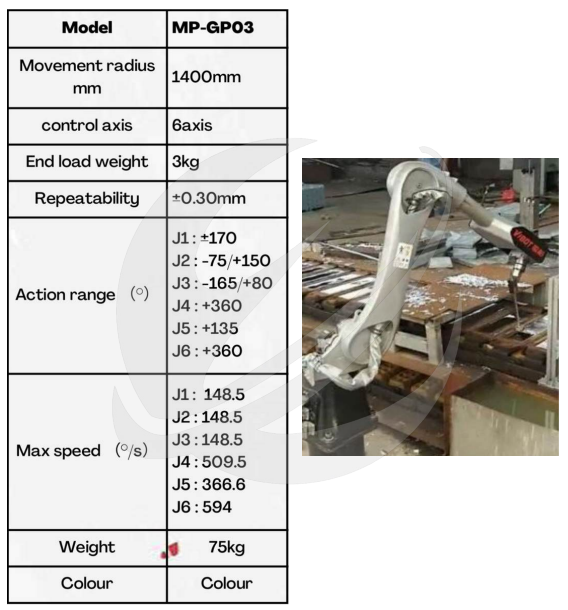

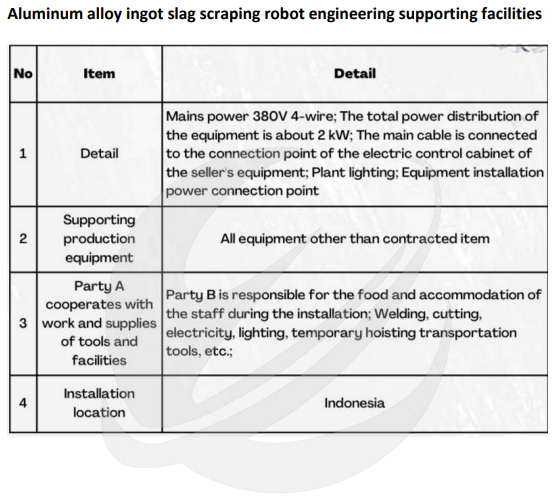

| Slag Robot |

Our extensive product portfolio includes:

Exceptional performance and durability for high-temperature applications, ensuring optimal thermal management.

High-performance materials for various applications.

Superior insulation solutions for energy efficiency.

Customizable options for effective thermal management.

Durable solutions for various aluminium extrusion processes.

Designed for enhanced performance and longevity.

Engineered for superior energy efficiency and user-friendliness.